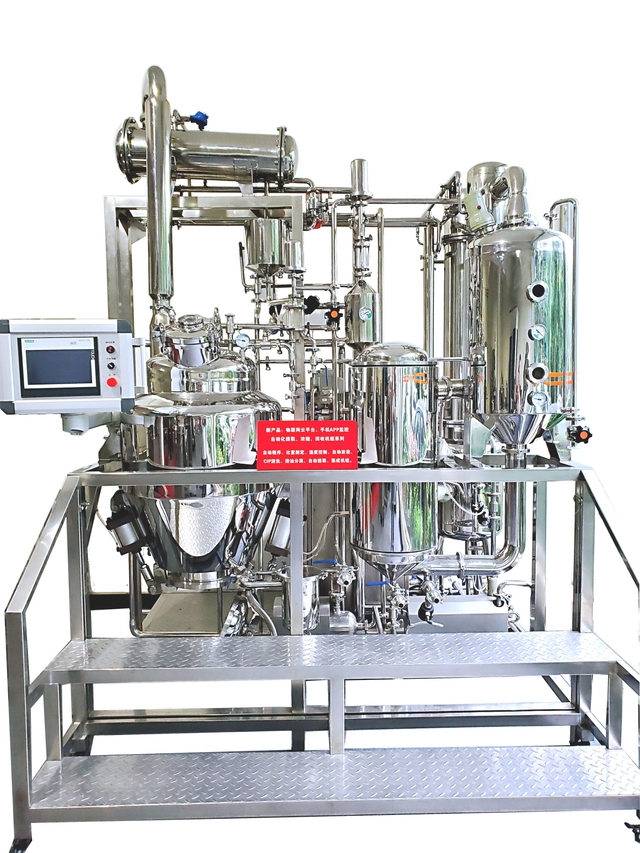

Product Display

▄▄

100L Extraction and concentration recovery unit

▄▄

主要用途(Main Usage)

该机组适用于中药、生化、食品、化工等行业的常压、水煎、温浸、强循环渗漉、芳香油提取及有机溶媒回收等多种工艺操作。

适用于提取液、中药、植物、动物、食品、化工液料的浓缩。特别适用于热敏性物料(例如中药生产的水、醇提取液、抗生素发酵液、牛奶、果汁等)在真空低温条件下浓缩,可确保产品质量。广泛用于中小药厂、实验工厂、医院、科研部门研制新药及新工艺提取与浓缩。

特点(Characteristics)

动态常压提取率高于静态的提取率。水提或醇提过程中,循环泵运转,使药液外循环,提取率大大高于静态的提取率,缩短了提取时间,节约能源。

可提取高含量的药物芳香油,从油水分离器中取出。外循环真空蒸发浓缩,效率高是突出的优点。料液在加热器被加热至所需沸点后,产生向上运动的热动力--浓缩罐内料液与加热器内料液产生重度差,浓缩罐内料液从下流进加热器,从加热器上部循环管流出,形成了料液的自然外循环流动,加快了料液热量吸收速度。料液在低温真空条件下沸腾,水份(或醇等)大量蒸发,加快了浓缩过程,浓缩比重大。

可真空回收酒精,蒸馏挥发油等。

本机组与料液接触的部位均采用不锈钢制成,管路为卫生级管路,符合“GMP”要求。

提取罐加热方式为盘管式加热。

The unit applies to Chinese medicine, biochemistry, food and chemical industry pressure, decoction, temperature Baptist, strong cycle shenlu dialysis, extraction of essential oil and organic solvent recovery operations, etc. Process

Applied to extract, traditional chinese medicine, plants, animals, food, liquid chemical concentration. Especially suitable for heat-sensitive materials (such as traditional Chinese medicine production of water, alcohol extract, antibiotic fermentation broth, milk, juice, etc.) at low temperatures in a vacuum concentration to ensure product quality. Widely used in small and medium-sized pharmaceutical, pilot plants, hospitals, research departments to develop new drugs and new technology of extraction and enrichment

Dynamic pressure is much higher than the static rate of extraction of the extraction rate. Water extract or alcohol extract process, the circulating pump starts, so that liquid pharmceutical extrinsic circle, the extraction rate is much higher than the static extraction ,and this can shortened the extraction time, energy.

High levels of drug aromatic oil can be extracted from the oil-water separator. Outside the circle of vacuum evaporation, high efficiency and to highlight the advantages. Liquid in the heater is heated to the boiling point, the resulting upward movement of the thermal power - concentrated liquid tank with the heater inside the liquid have a serious difference, concentrated liquid from the tank into the heater downstream from the heater outflow of the upper part of the cycle tube, forming a liquid outside the circle of the natural flow of the liquid to speed up the rate of heat absorption. Liquid at low temperatures under vacuum conditions of boiling, water (or alcohol, etc.) a large number of evaporation and speed up the enrichment process, significant enrichment than

Alcohol recovery may be a vacuum distillation of volatile oil

The unit in contact with the liquid parts are made of stainless steel, pipe line for health class, In line with the "GMP" requirements.

Heating method is the coil heater.

技术参数(technical data)

提取罐容积(L) extracting tank capacity | 100 | 提取温度(℃) Concentrating temperature | 45~100 |

浓缩罐容积(L) Concentrating tank capacity | 100 | 药液循环泵功率(KW) Power of circulating pump for liquid pharmacutical product | 0.75 |

提取罐夹套工作压力 Jacket pressure of extracting tank | 常压 Atmospheric pressure | 水循环真空泵功率(KW) Power of water circulating vacume pump | 2.2 |

提取罐内工作压力 Inner pressure of extracting tank | 常压Atmospheric pressure | 温度显示范围 Temperature indication range | 0~200 |

加热方式 Heat method | 盘管式加热 Coil heating | 浓缩真空度(MPa) Concentration vacume degree | 0.05~0.08 |

浓缩温度(℃) Concentrating temperature | 45~100 |

|

Professional , intelligent , innovation , sincerity

Copyright @ 2017 www.yt-yj.com ALL Rights Reserved | 成都永泰制药工厂机械 | 蜀ICP备19031122号

联系电话:028 - 87333888传真电话:028 - 87333999

技术服务:028 - 87347304地址:中国۰成都温江永宁国际医学城۰永福街205号